Stratasys’ annual Extreme Redesign Challenge (ERC) has encouraged participants to think differently about how they see products, devices and the world around them. From modified cell phone cases to assistive devices, students from New England-based schools were recognized for their innovations during AET Labs’ Extreme Redesign Competition and Digital Fabrication Showcase.

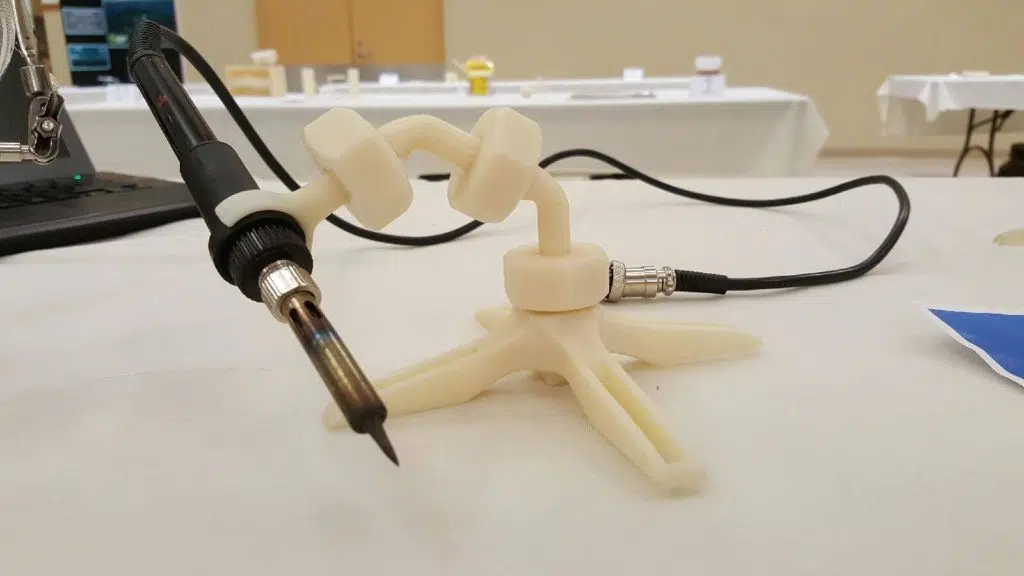

3D Printed Active Soldering Iron Stand provides unrestricted use of hands and improved stability and mobility. 3D printed on the Stratasys uPrint SE Plus.

The competition was held at Worcester Polytechnic Institute in Worcester, Massachusetts, and was coupled with a digital fabrication showcase to educate the 100+ participants on various types of manufacturing technologies. Students and instructors had the opportunity to hear from Steve Chomyszak, assistant professor of mechanical engineering and technology at the Wentworth Institute of Technology, who played an integral role in the development of the Stratasys curriculum for post-secondary education.

“3D printing encourages you to screw up and have fun doing it. Iteration is at your fingertips, and iteration is good for learning,” said Chomyszak during his presentation to students. “Don’t be afraid of failure. You learn more from getting things wrong than from always doing things right.”

And while a fear of failure can affect ones motivation to learn, these young contestants demonstrated an uninhibited imagination that encouraged them to try something new, fail and try again.

“We learned that it’s okay to fail, because sometimes things won’t be perfect,” said JR Koshivas of Tri-County Regional Vocational Technical High School in Franklin, Massachusetts. “Don’t be afraid to branch out. This design contest can really help you discover what you’re good at.”

Students drew from their own experiences and interests to develop solutions to existing problems.

Koshivas and his teammate, Vin Polito, developed a camera case equipped with a storage unit for USB drives. ERC semi-finals runner-up, Kevin Kohls of Tri-County Regional, created a 3D printed active soldering iron stand. The stand gives users unrestricted use of their hands, while also working as a guide to improve stability.

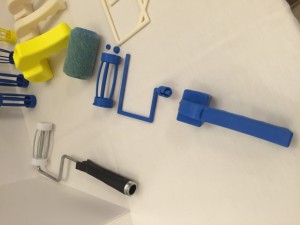

ERC semi-finalist winner, Kathleen Kolhstrom, a student at Tantasqua Regional High School in Fiskdale, Massachusetts, created the Extreme Roller. Inspired by her personal experience with painting, her ergonomic design fits more comfortably in the hands of users and can be disassembled for easy clean-up.

Kohlstrom credits 3D printing for accelerating her iterative design process in order to meet the competition deadline. “I would not have finished this project without 3D printing. The firs t handle I made was too big, so I had to evolve my design to make it smaller,” said Kolhstrom. “As I was 3D printing the handles, I could touch them and change the sizing and tolerance fit. It helped to have something tangible.”

Kohlstrom’s teacher and mentor, Raymond Vallee, has been involved with the Extreme Redesign challenge for a few years and shared his secret to creating a fun learning environment for students. “The best way to inspire students is to have them research projects and products that they already have some first-hand knowledge about. It’s easier to redesign a product if you’re familiar with it.”

AET Labs’ Extreme Redesign Competition and Digital Fabrication Showcase Finalists

Watch these video interviews with the semi-finalists to learn how they turned their ideas into reality with Stratasys 3D printing:

1st place: The Extreme Roller- Kathleen Kolhstrom, Tantasqua Regional Vocational High School

Watch Kathleen’s redesign here

The winners of the Extreme Redesign 3D Printing Challenge 2016 will be announced in April. For more information, please visit http://www.stratasys.com/extremeredesign.